Languages

Products

telephone

(+39)0773.52.30.14

fax

(+39)06.233.234.260

e-mail

info@sinergroup.it

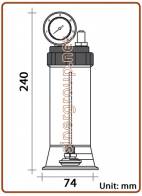

Carbonation test Co2 quality test volumes

Informations

Code:

13006001

Weight:

0.5 Kg

Description

Carbonation test Co2 quality test volumes

click on images to enlarge

Full description

MEASURING CUP CARBONATION

Note: for use with post-mix dispensed beverages only.

1. Pre-cool the cup with ice or by filling with cold product and then empty.

2. Immediately dispense sample product into a cup larger than the test chamber.

Note: The cup should be held close to the nozzle and tilted to reduce foaming.

3. Carefully transfer the sample into the test chamber until completely full.

4. Place the cap on the test chamber and screw closed.

5. Depress the vent valve until the gauge reads zero, then release.

6. Gently swirl the tester until gauge reads 5 PSIG. Again release the pressure using the vent valve.

7. Shake the tester vigorously until the pressure stabilizes at the highest reading.

8. Read down the temperature heading column to that indicated on the thermometer in the tester base. Then read across the pressure heading row to that indicated on the gauge. The number at the intersection of the temperature and pressure readings is the volume of CO2 in the sample. Measure samples until readings agree.

SETTING CARBONATOR PRESSURE

1. Take the desired cup carbonation value and add 1 volume to obtain in-line value.

2. Divide the in-line value by carbonator efficiency (usually 80%) to obtain ideal value.

IDEAL VALUE= in-line value / 0.8

3. Read down the temperature heading column to that indicated on the thermometer. Go across the temperature row to the ideal value. Read the pressure column heading above the ideal volume reading.

Note: the ideal carbonator pressure should be adjusted as needed by measuring actual cup carbonator values.

THERMOMETER FIELD ADJUSTMENT

1. Turn nut under thermometer approximately 1 turn counterclockwise using 9/16" open end wrench inserted through slot in base of carbonation tester.

2. Remove thermometer by pulling on the thermometer housing and twisting while holding tester cup steady.

3. Insert thermometer stem, into an ice-water container and stir vigorously for one minute. The thermometer should indicate 32°F (0°C).

4. If it dopes not, grasp the flats on the metal housing with pliers and turn the plastic face with one's hand until 32°F (0°C) is indicated.

5. Wth the stem still wet, insert the thermometer by pressing in while twisting.

6. Tighten the retaining nut 1 turn.

7. Check the thermometer by filling the test chamber with the ice-water mixture and reading 32°F (0°C).

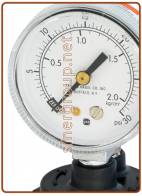

PRESSURE GAUGE FIELD ADJUSTMENT

1. The gauge has been factory calibrated and will indicate within the zero band when the tester is depressurized.

2. If the gauge does not indicate within the zero band when depressurized, unscrew the clear plastic cover.

3. Carefully turn the adjusting stem until the pointer is centered in the zero band.

4. Replace the cover.

5. For absolute accuracy, calibration of the gauge must be done with a calibrated test pressure gauge.

Note: for use with post-mix dispensed beverages only.

1. Pre-cool the cup with ice or by filling with cold product and then empty.

2. Immediately dispense sample product into a cup larger than the test chamber.

Note: The cup should be held close to the nozzle and tilted to reduce foaming.

3. Carefully transfer the sample into the test chamber until completely full.

4. Place the cap on the test chamber and screw closed.

5. Depress the vent valve until the gauge reads zero, then release.

6. Gently swirl the tester until gauge reads 5 PSIG. Again release the pressure using the vent valve.

7. Shake the tester vigorously until the pressure stabilizes at the highest reading.

8. Read down the temperature heading column to that indicated on the thermometer in the tester base. Then read across the pressure heading row to that indicated on the gauge. The number at the intersection of the temperature and pressure readings is the volume of CO2 in the sample. Measure samples until readings agree.

SETTING CARBONATOR PRESSURE

1. Take the desired cup carbonation value and add 1 volume to obtain in-line value.

2. Divide the in-line value by carbonator efficiency (usually 80%) to obtain ideal value.

IDEAL VALUE= in-line value / 0.8

3. Read down the temperature heading column to that indicated on the thermometer. Go across the temperature row to the ideal value. Read the pressure column heading above the ideal volume reading.

Note: the ideal carbonator pressure should be adjusted as needed by measuring actual cup carbonator values.

THERMOMETER FIELD ADJUSTMENT

1. Turn nut under thermometer approximately 1 turn counterclockwise using 9/16" open end wrench inserted through slot in base of carbonation tester.

2. Remove thermometer by pulling on the thermometer housing and twisting while holding tester cup steady.

3. Insert thermometer stem, into an ice-water container and stir vigorously for one minute. The thermometer should indicate 32°F (0°C).

4. If it dopes not, grasp the flats on the metal housing with pliers and turn the plastic face with one's hand until 32°F (0°C) is indicated.

5. Wth the stem still wet, insert the thermometer by pressing in while twisting.

6. Tighten the retaining nut 1 turn.

7. Check the thermometer by filling the test chamber with the ice-water mixture and reading 32°F (0°C).

PRESSURE GAUGE FIELD ADJUSTMENT

1. The gauge has been factory calibrated and will indicate within the zero band when the tester is depressurized.

2. If the gauge does not indicate within the zero band when depressurized, unscrew the clear plastic cover.

3. Carefully turn the adjusting stem until the pointer is centered in the zero band.

4. Replace the cover.

5. For absolute accuracy, calibration of the gauge must be done with a calibrated test pressure gauge.

Bestsellers