Languages

Products

telephone

(+39)0773.52.30.14

fax

(+39)06.233.234.260

e-mail

info@sinergroup.it

Pressure tanks 6x13 Thread 2 1/2-0 (A307-B338-C344-D155-E159-F94) 4lit. w/o base (12)

Informations

Code:

15015601-005

Weight:

2 Kg

Description

Pressure tanks 6x13 Thread 2 1/2-0 (A307-B338-C344-D155-E159-F94) 4lit. w/o base (12)

click on images to enlarge

Full description

High mechanical resistance pressure tanks made of an internal HD food-suitable polyethylene liner and of an outer covering in reinforced glassfiber and resin.

1* The polyethylene is the raw material used to produce the tank.

2* The liner is the basic semifinished product. The different sizes are produced on the basis of statistics.

3* The blow moulding is one of the most complex and crucial stages of the entire production cycle.

4* Fiberglass and resin are the basic products of outer laminate of the tank. These raw materials have to be mixed with other components in accordance with an exclusive HST method in order to guarantee resistance and elasticity.

5* The filament winding is the last stage of the production cycle in which all the experience and know-out of HST concentrate. Every detail is of primary importance to obtain the best result: the different true clearances of the two winding methods (radial and helicoidal ), the forward speed of fiberglass thread and the forward speed of liner rotation, the constant tension of fiberglass thread, the right temperature, these are only some details which have to be constantly checked in order to obtain the best result.

6* The tests check the product and verify if its quality is conformed to the quality standard.

7* Once the tank has been produced and tested, it is stored in specific areas, ready to be shipped.

Features

Inner polyethylene liner in reinforced fiberglass* Working pressure: > min 0 bar > max 10 bar (tanks 5” to 18”), > min 0 bar > max 8 bar (tanks 21” to 36”) * Working temperature: > min 1°C > max 50°C.

Control data

Testing pressure: 0-10 bar. * Burst pressure at 250.000 fatigue cycles between 0-10 bar: Over 32 bar * 3" * Cracking test after 52 hours of polymerization: 45bar.

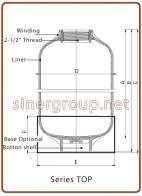

Top tank series

A thread on the top of the tank.

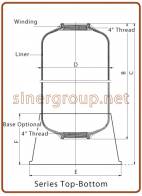

Top-bottom tank series

Two threads: one thread on the top and the other one at the bottom of the tank.

Sizing according to the softener tank to be built

Suppose you need to assemble a water softener 30 liter, the calculation to be made is 39x0, 8 = 31.20 (39 liters are the ability of the cylinder x 0.8 fixed coefficient = 31.20 liters is the result of resin to be introduced in the cylinder)

1* The polyethylene is the raw material used to produce the tank.

2* The liner is the basic semifinished product. The different sizes are produced on the basis of statistics.

3* The blow moulding is one of the most complex and crucial stages of the entire production cycle.

4* Fiberglass and resin are the basic products of outer laminate of the tank. These raw materials have to be mixed with other components in accordance with an exclusive HST method in order to guarantee resistance and elasticity.

5* The filament winding is the last stage of the production cycle in which all the experience and know-out of HST concentrate. Every detail is of primary importance to obtain the best result: the different true clearances of the two winding methods (radial and helicoidal ), the forward speed of fiberglass thread and the forward speed of liner rotation, the constant tension of fiberglass thread, the right temperature, these are only some details which have to be constantly checked in order to obtain the best result.

6* The tests check the product and verify if its quality is conformed to the quality standard.

7* Once the tank has been produced and tested, it is stored in specific areas, ready to be shipped.

Features

Inner polyethylene liner in reinforced fiberglass* Working pressure: > min 0 bar > max 10 bar (tanks 5” to 18”), > min 0 bar > max 8 bar (tanks 21” to 36”) * Working temperature: > min 1°C > max 50°C.

Control data

Testing pressure: 0-10 bar. * Burst pressure at 250.000 fatigue cycles between 0-10 bar: Over 32 bar * 3" * Cracking test after 52 hours of polymerization: 45bar.

Top tank series

A thread on the top of the tank.

Top-bottom tank series

Two threads: one thread on the top and the other one at the bottom of the tank.

Sizing according to the softener tank to be built

Suppose you need to assemble a water softener 30 liter, the calculation to be made is 39x0, 8 = 31.20 (39 liters are the ability of the cylinder x 0.8 fixed coefficient = 31.20 liters is the result of resin to be introduced in the cylinder)

Related products